EFFICIENT WASTEWATER TREATMENT

Thanks to its unique properties, HOK® Activated Lignite has been successfully used in environmental technologies for water treatment for a number of years. Its suitability for a wide range of applications makes the sorbent a tried-and-tested part of biological and adsorptive water treatment processes in a number of industries. HOK® Activated Lignite is used, for example:

- in biotechnology for biological wastewater treatment

- as a filter in drinking water plants

- as an adsorbent for treating leachate and industrial wastewater

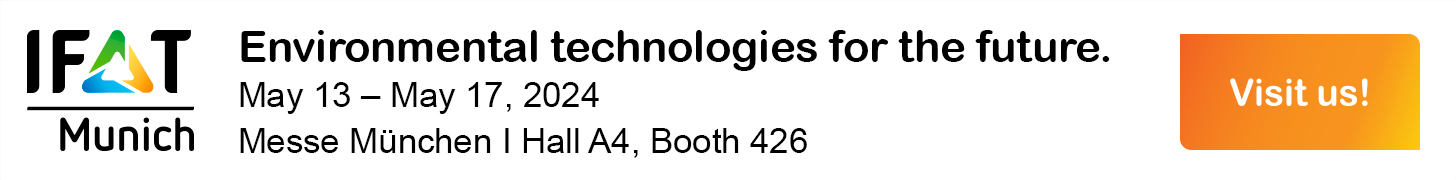

BIOLOGICAL WASTEWATER TREATMENT

HOK® Activated Lignite Pulverized, which is produced using a grinding process, is particularly widely-used in biological wastewater treatment. Grains suitable for use in fixed beds and stirred-tank reactors are available as HOK® Activated Lignite Medium or HOK® Activated Lignite Grained. Strict environmental regulations and frequently inadequate degradation capacity in existing plants can force operators to cope with significant cost increases. Expensive chemicals, along with conversion and expansion work, can push up operating costs. This is why today’s biological and adsorptive procedures were developed to solve the widest possible range of problems associated with water treatment.

HOK® Activated Lignite’s effectiveness in biological wastewater treatment is based on the so-called ‘feeding trough model’. Individual HOK® Activated Lignite particles can be viewed as a ‘feeding trough’, from which the surrounding micro-organisms can obtain oxygen and nutrients.

These nutrients, specifically the unwanted substances within the wastewater and oxygen, are available in greater and consistent concentrations within the HOK® Activated Lignite particles than in the surrounding water. As a result of continuing adsorption and desorption, the HOK® Activated Lignite particles act as a buffer and temporary storage – they reduce variation in load and in the surrounding environment.

The HOK® Activated Lignite-based biological process produces a compact, rapidly sedimenting mud. The increased concentration of mud in the activated area leads to reduction in the sludge index and increased degradation capacity. This has the advantage of stabilizing the system as a whole at a high level of degradation. The HOK® Activated Lignite support structure also encourages sludge drainage, reducing the amount of conditioner required. HOK® Activated Lignite can also be used in fixed-bed biological processes for smaller quantities of wastewater and other specific applications.

HIGH-QUALITY FILTER MATERIAL

Using HOK® Activated Lignite as a high-quality filter material allows all harmful substances related to emissions to be captured, including sulphur dioxide, hydrogen chloride, hydrogen fluoride, heavy metals (Hg, Cd, As, Pb etc.), dioxin and furan as well as a wide range of organic components.

SIMPLE AND SAFE TO USE

From a fire safety technology standpoint, HOK® Activated Lignite is an inert material, making it suitable for use even at high temperatures. Manufacturing it at temperatures in excess of 900°C expels almost all combustible primary volatile matter.

PLENTIFUL, SECURE SUPPLY

RWE Power AG is one of the world’s largest producers of activated lignite with an annual production capacity of approximately 200,000 tonnes.

HOK® Activated Lignite – A FRESH, NON-REGENERATED SORBENT

HOK® Activated Lignite is an exclusively ‘fresh sorbent’, which does not contain any thermally regenerated used activated lignite (so-called ‘regenerates’), which pick up harmful substances prior to regeneration as a result of industrial use.

PRODUCTION, SALES AND LOGISITCS ALL IN ONE PLACE

Production, sales and logistics activities are all carried out in accordance with a consistent quality control process based on DIN EN ISO 9001:2015, and are an integral part of our Refining business.

KNOW-HOW AND ADVICE

Rheinbraun Brennstoff GmbH’s highly-qualified team of advisers, including both engineers and sales staff, brings together decades of experience in using HOK® Activated Lignite and the insights gained from working with our customers.

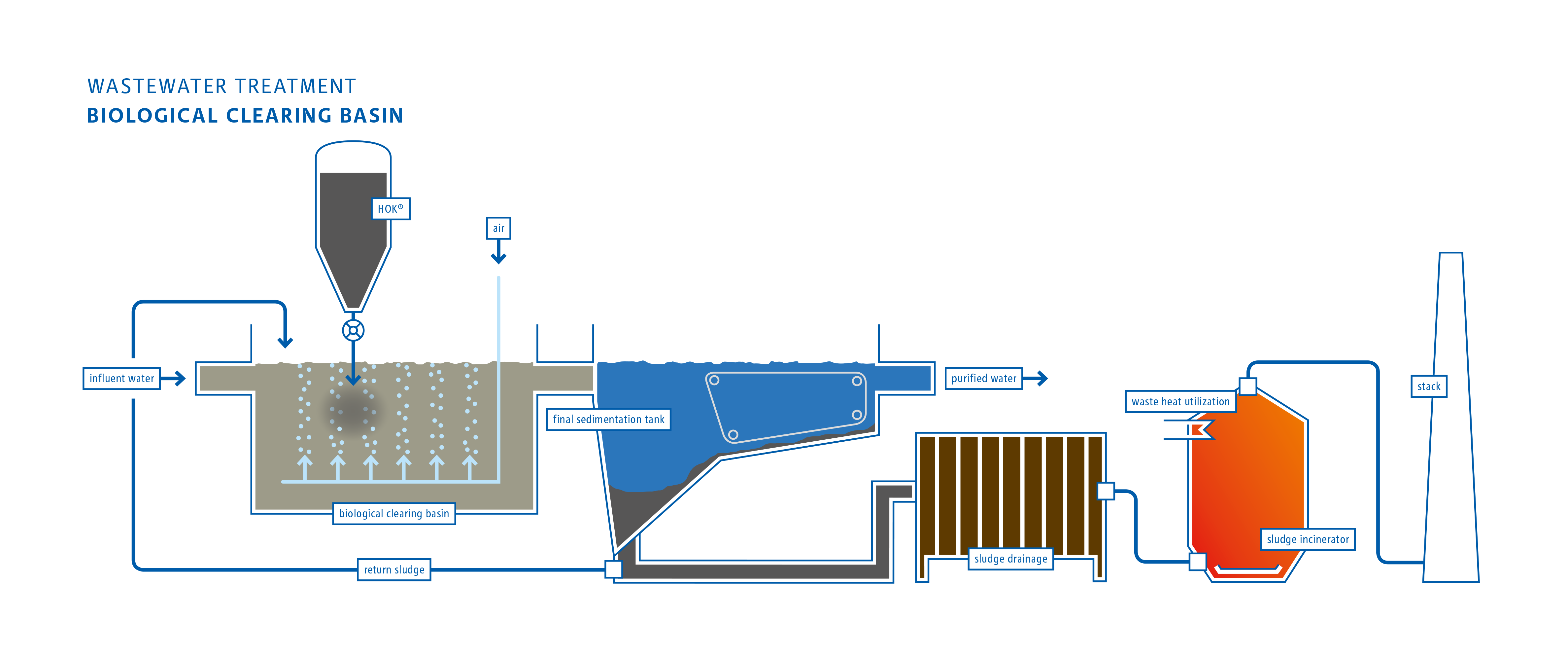

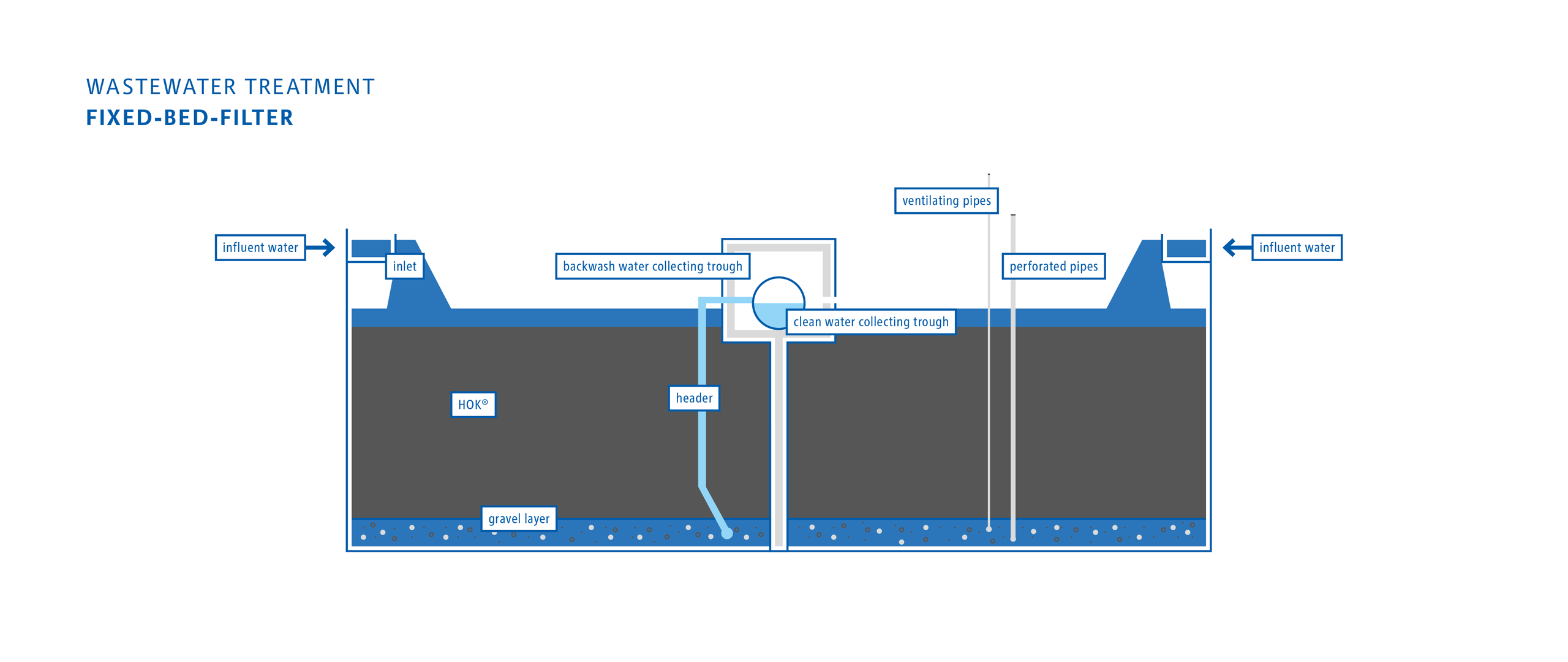

ADSORPTIVE WASTEWATER TREATMENT

Besides competitively-priced biological wastewater treatment, an adsorptive treatment process is required for substances that are particularly difficult to degrade. Large-molecule compounds have a particular tendency to adhere to HOK® Activated Lignite. From a technical point of view, adsorption processes like these can be set up using a suspension technique or as a fixed-bed filter, depending on the range of concentrations involved.

For processes using suspension techniques, stirred-tank reactors are used, and are set up as single or multi-level countercurrent cascades as required. The advantages of using the suspension technique include a large mass transfer and – thanks to the cascade – the ability to load the activated lignite with large quantities of harmful substances plus continuous plant operation.

In the fixed-bed option, which can be based on biological or adsorptive processes or on a combination of both by varying ventilation, the water to be treated flows through a solid HOK® Activated Lignite bed. If the water level is lowered below the HOK® Activated Lignite surface, the free HOK® Activated Lignite on the top captures odorants by adsorption. Targeted backwashing ensures that the filter will achieve a long service life and that the HOK® Activated Lignite is loaded with sufficient quantities of harmful substances.

ANALYSIS REFERENCE VALUES HOK®

| Water content | 0,5 % |

| Ash content | 9,0 % |

| Volatile matter (primarily CO & CO2) | 3,0 % |

| Fixed carbon | 87,5 % |

| BET (spec. surface) | 300 m²/g (+/-30) |