PROFITABLE WASTE GAS TREATMENT

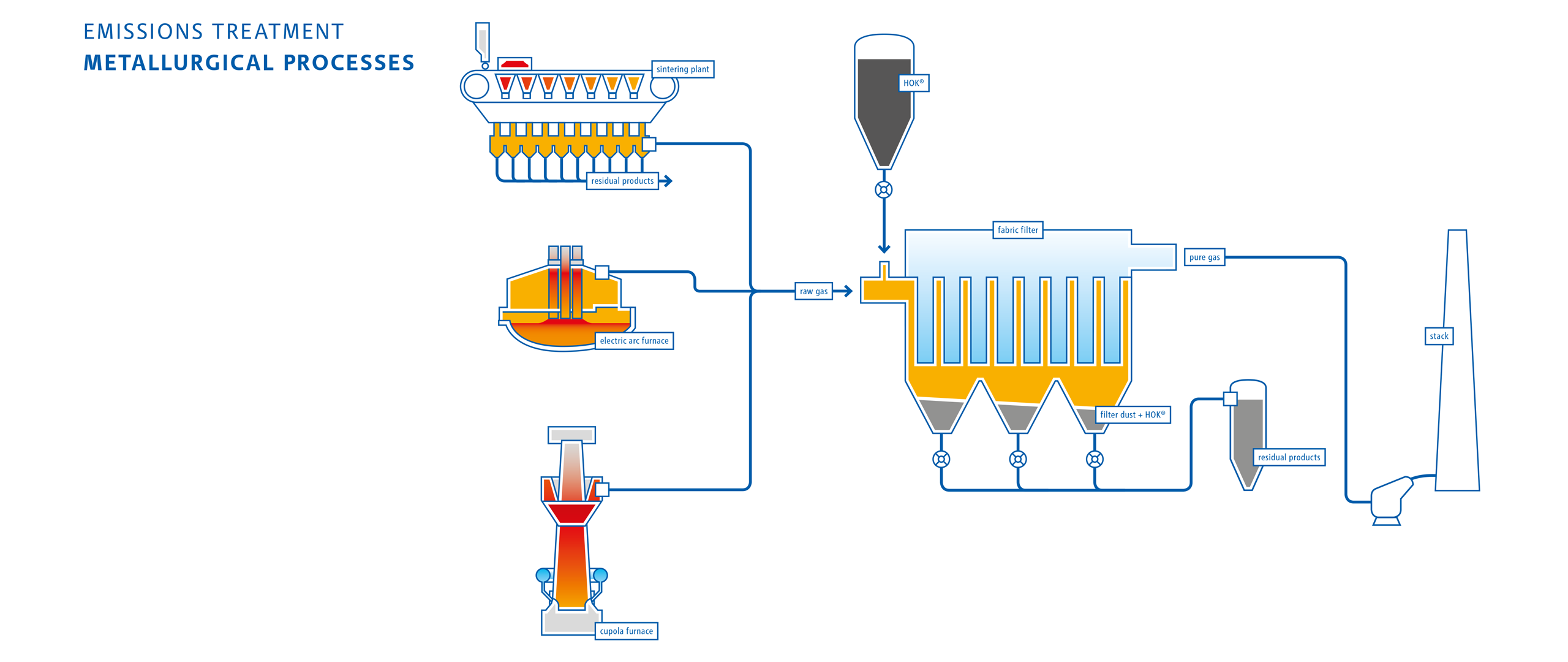

HOK® Activated Lignite is a highly-efficient filter material used to capture harmful substances in emissions. Thanks to its excellent treatment performance, the sorbent is used particularly frequently in waste and hazardous waste incinerators and for treating process gases in the metal industry.

HOK® Activated Lignite removes a wide range of harmful substances from emissions through adsorption, chemisorption or catalytic conversion.

Quantities of all the following harmful substances can be brought under the detection limit using HOK® Activated Lignite:

- heavy metals such as mercury (Hg), cadmium (Cd), arsenic (As) or lead (Pb)

- sulphur dioxide (SO2)

- hydrogen chloride (HCL)

- hydrogen fluoride (HF)

A WIDE RANGE OF APPLICATIONS

Thanks to its unique properties, HOK® Activated Lignite is used in a number of environmental applications, for example, as a sorbent in emissions and exhaust treatment.

HOK® Activated Lignite’s favourable porous structure, with a high proportion of mesopores and macropores (1 to 50 nm) makes the internal surface easily accessible. This is key for adsorption of large-molecule compounds, for example, dioxins and furans.

When used alongside technologies already available on the market, HOK® Activated Lignite’s unique characteristics can keep levels of harmful emissions from waste and hazardous waste incinerators well within the proscribed limits.

HIGH-QUALITY FILTER MATERIAL

Using HOK® Activated Lignite as a high-quality filter material allows all harmful substances related to emissions to be captured, including sulphur dioxide, hydrogen chloride, hydrogen fluoride, heavy metals (Hg, Cd, As, Pb etc.), dioxin and furan as well as a wide range of organic components.

SIMPLE AND SAFE TO USE

From a fire safety technology standpoint, HOK® Activated Lignite is an inert material, making it suitable for use even at high temperatures. Manufacturing it at temperatures in excess of 900°C expels almost all combustible primary volatile matter.

PLENTIFUL, SECURE SUPPLY

RWE Power AG is one of the world’s largest producers of activated lignite with an annual production capacity of approximately 200,000 metric tons.

HOK® Activated Lignite – A FRESH, NON-REGENERATED SORBENT

HOK® Activated Lignite is an exclusively ‘fresh sorbent’, which does not contain any thermally regenerated used activated lignite (so-called ‘regenerates’), which pick up harmful substances prior to regeneration as a result of industrial use.

PRODUCTION, SALES AND LOGISITCS ALL IN ONE PLACE

Production, sales and logistics activities are all carried out in accordance with a consistent quality control process based on DIN EN ISO 9001:2015, and are an integral part of our Refining business.

KNOW-HOW AND ADVICE

Rheinbraun Brennstoff GmbH’s highly-qualified team of advisers, including both engineers and sales staff, brings together decades of experience in using HOK® Activated Lignite and the insights gained from working with our customers.

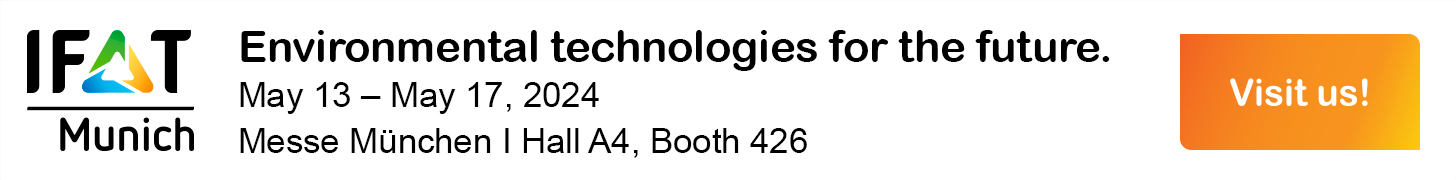

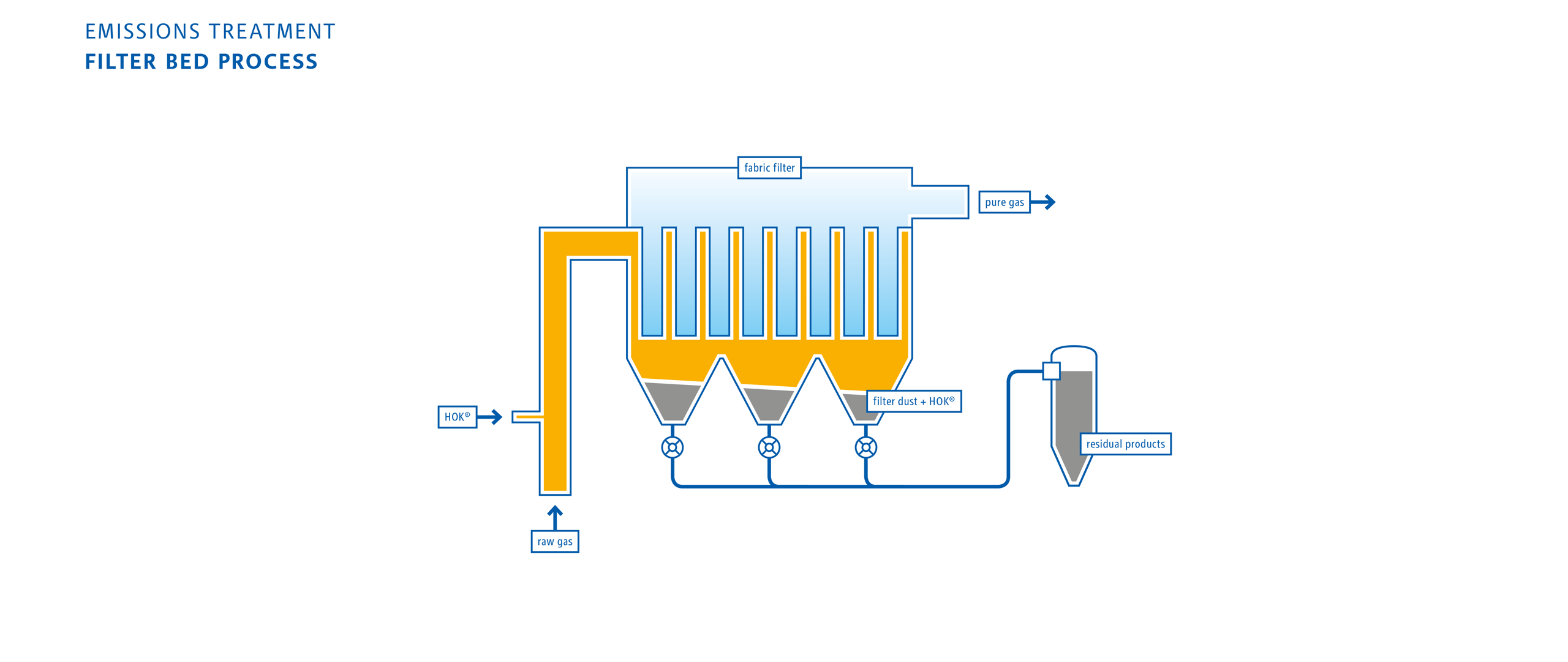

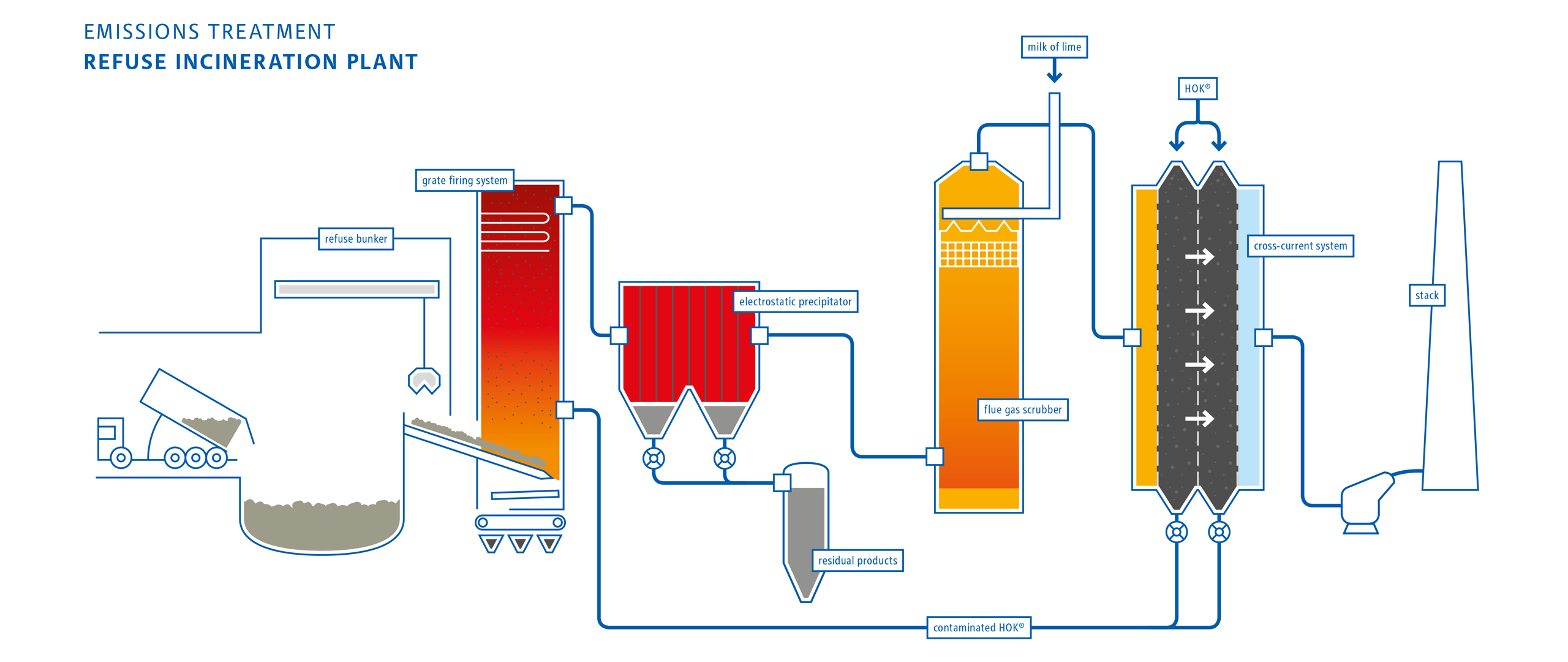

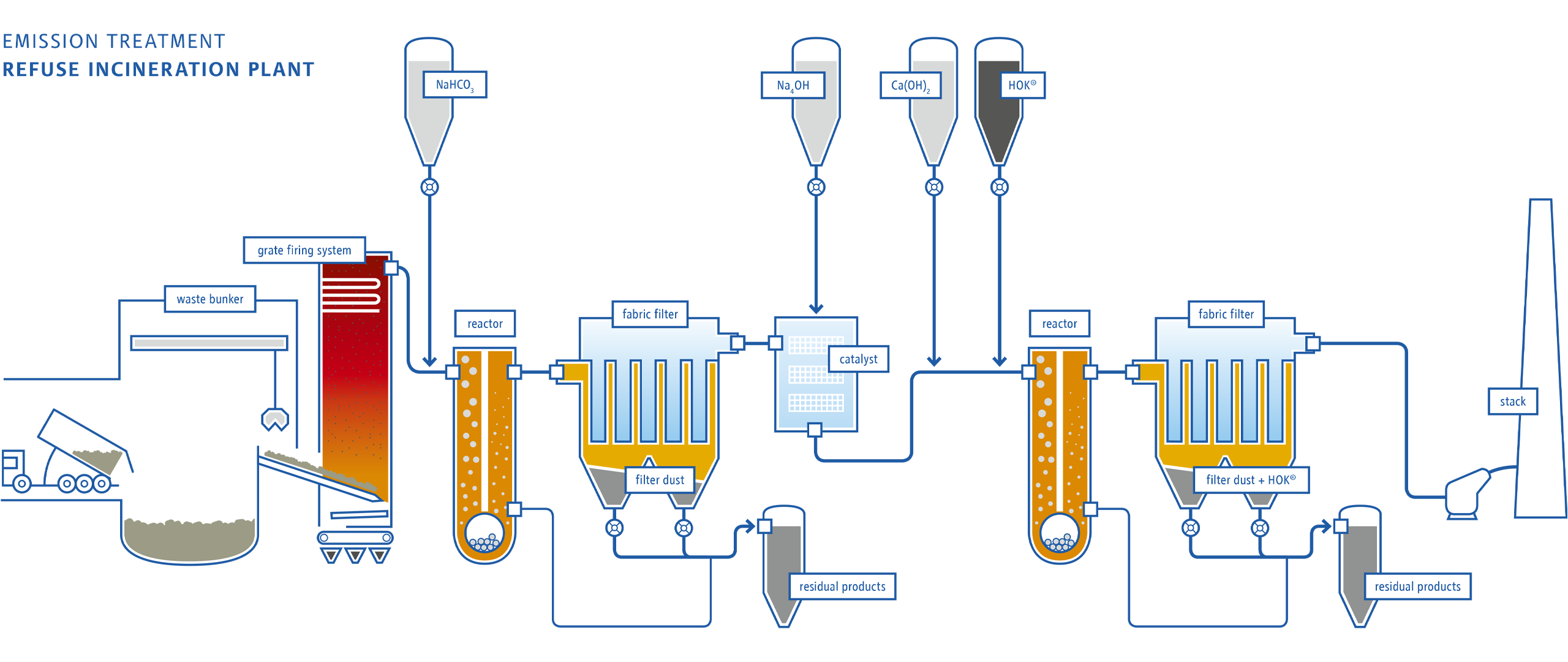

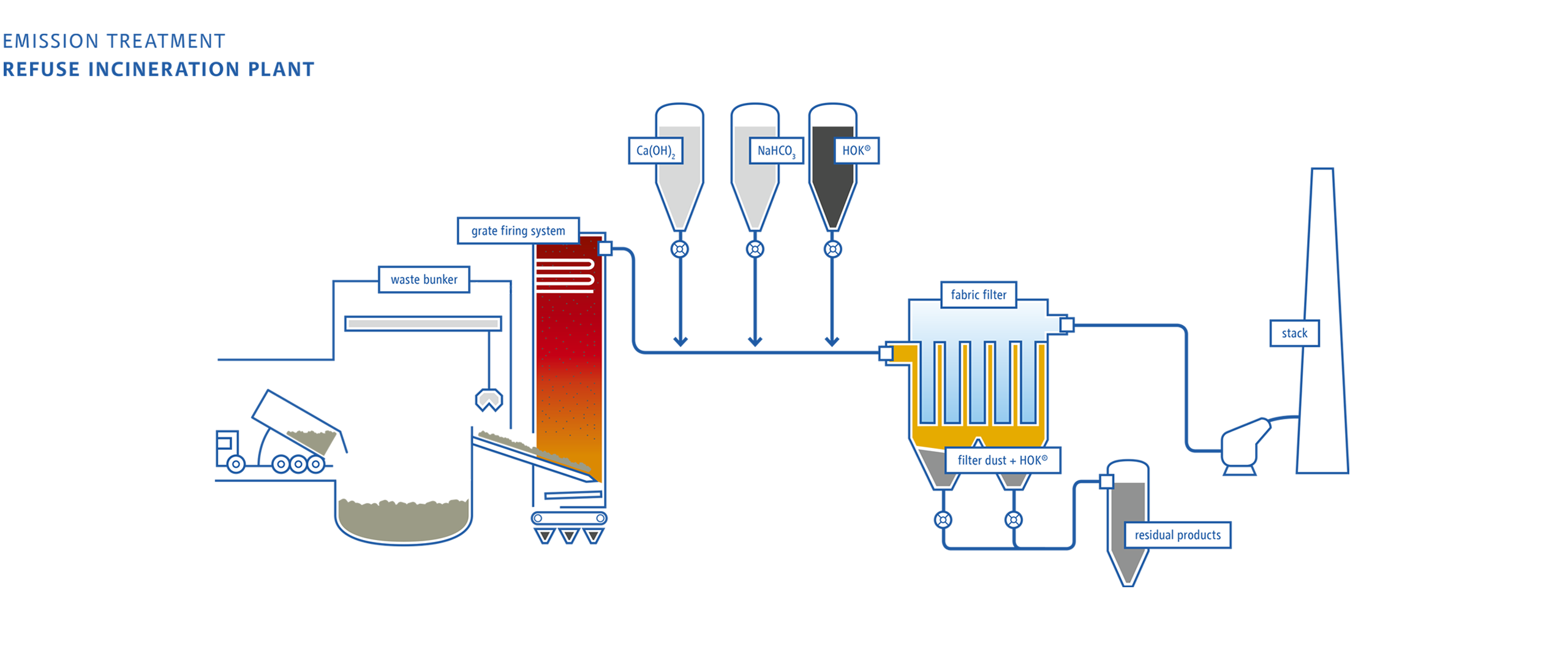

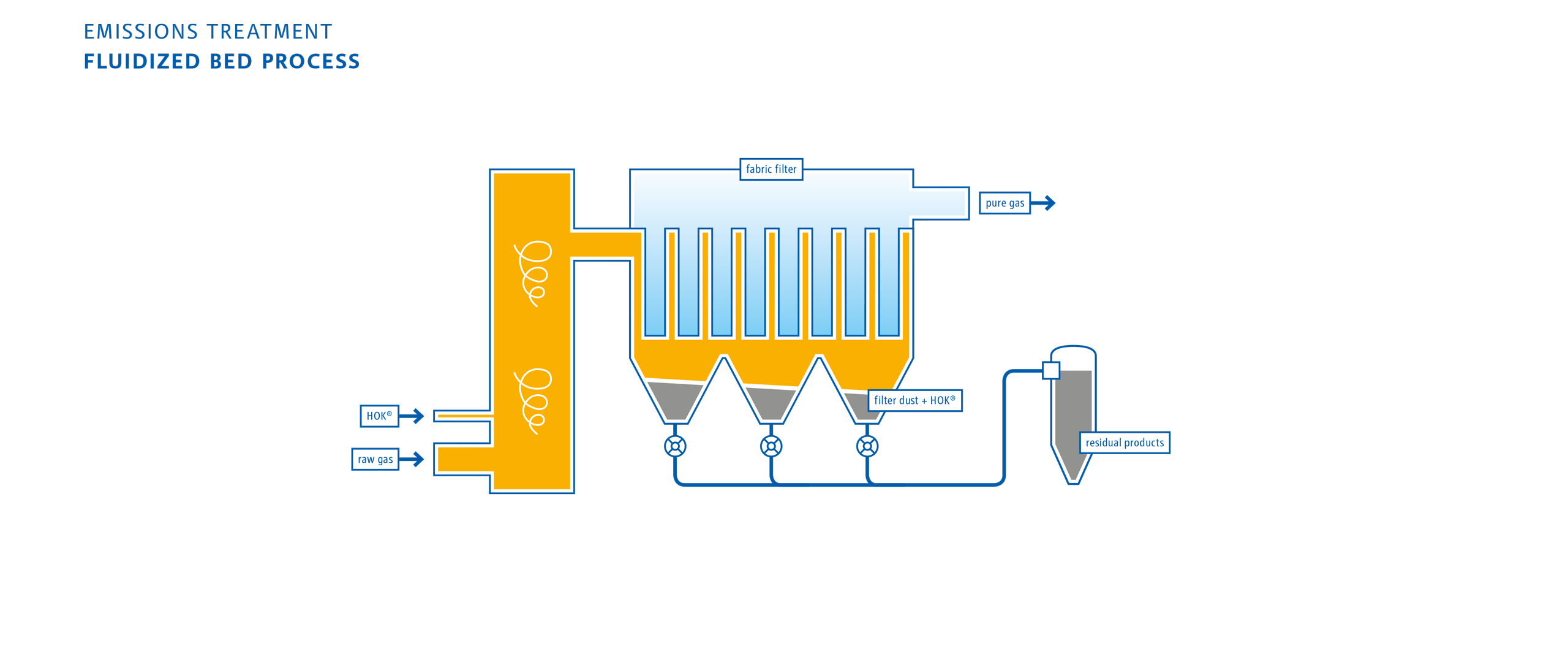

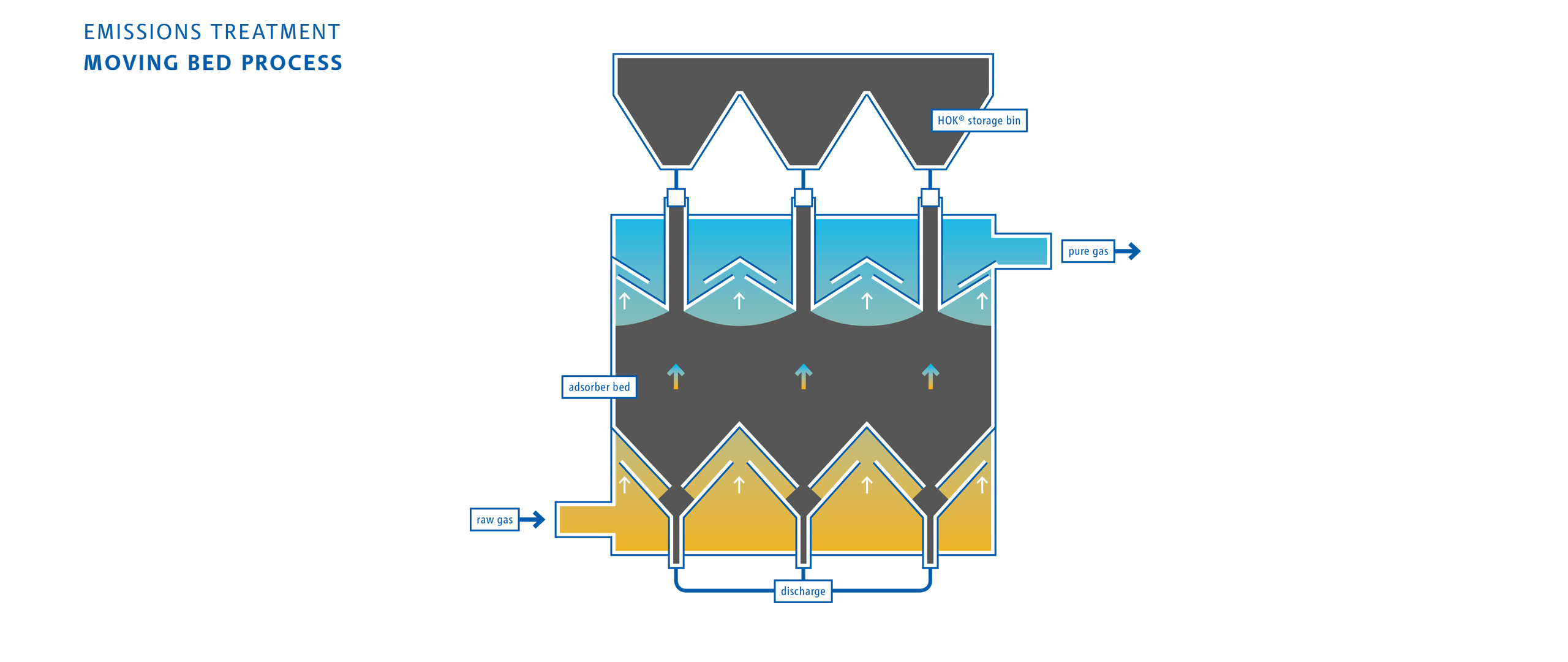

PROCEDURAL PLANS

A variety of different procedures have been developed for treating emissions from waste and hazardous waste incinerators using HOK® Activated Lignite. Today, these procedures are used in a huge number of processes for adsorptive treatment of emissions and exhaust fumes. Choosing the right procedure depends on the harmful substances to be captured, as well as their raw gas concentrations and the pure gas concentrations required.

These technologies have been fully integrated into existing plants and their procedures and fully tested on an industrial scale. They represent state of the art technology given the variety of applications for which they are currently used.

ANALYSIS REFERENCE VALUES HOK®

| Water content | 0,5 % |

| Ash content | 9,0 % |

| Volatile matter (primarily CO & CO2) | 3,0 % |

| Fixed carbon | 87,5 % |

| BET (spec. surface) | 300 m²/g (+/-30) |