GENERATING STEAM USING CO-GENERATION

LE Lignite Energy is an especially efficient source of energy for the cost-effective generation of process steam and power through co-generation. For example, this technology is used in the paper and sugar industries, in breweries and in other energy-intensive sectors requiring both process steam and electricity.

Rheinbraun Brennstoff (RBB) works with its partners to develop supply solutions for these customers generating from 5 to 300 MWth. RBB supports the planning and implementation of new generating plants and the conversion of existing boiler units to run on LE.

Operators of steam and power generation plants benefit from low energy prices over the long-term. RBB doesn’t just ensure a secure fuel supply either; it also ensures the ash is disposed of in an environmentally-friendly way.

NET CALORIFIC VALUE

RBB’s LE contains a high proportion of volatile matter, as well as boasting both a consistent grain size and a consistently low water content. This ensures ideal burning characteristics for profitable steam generation thanks to a nearly constant net calorific value.

SIMPLE AND SAFE TO USE

LEP Lignite Energy Pulverized and LEG Lignite Energy Grained are easy and safe to use in closed systems. In fact, they are just as simple to use as an oil-powered system. Delivery is by road in a silo, or by rail in a closed tank wagon.

HIGH CONTROL SPEED

LE combustion plants have a high control speed, allowing process steam generation to be adapted flexibly to production requirements.

MEETS STATUTORY EMISSIONS GUIDELINES

LE is a low-sulphur energy source, and the emissions it produces are well within statutory limits.

USING WASTE MATERIALS FOR THERMAL ENERGY

Waste materials in steam generation plants can be burned alongside LE to produce thermal energy. In many industries, this helps to keep constantly rising disposal costs under control.

STEAM GENERATION

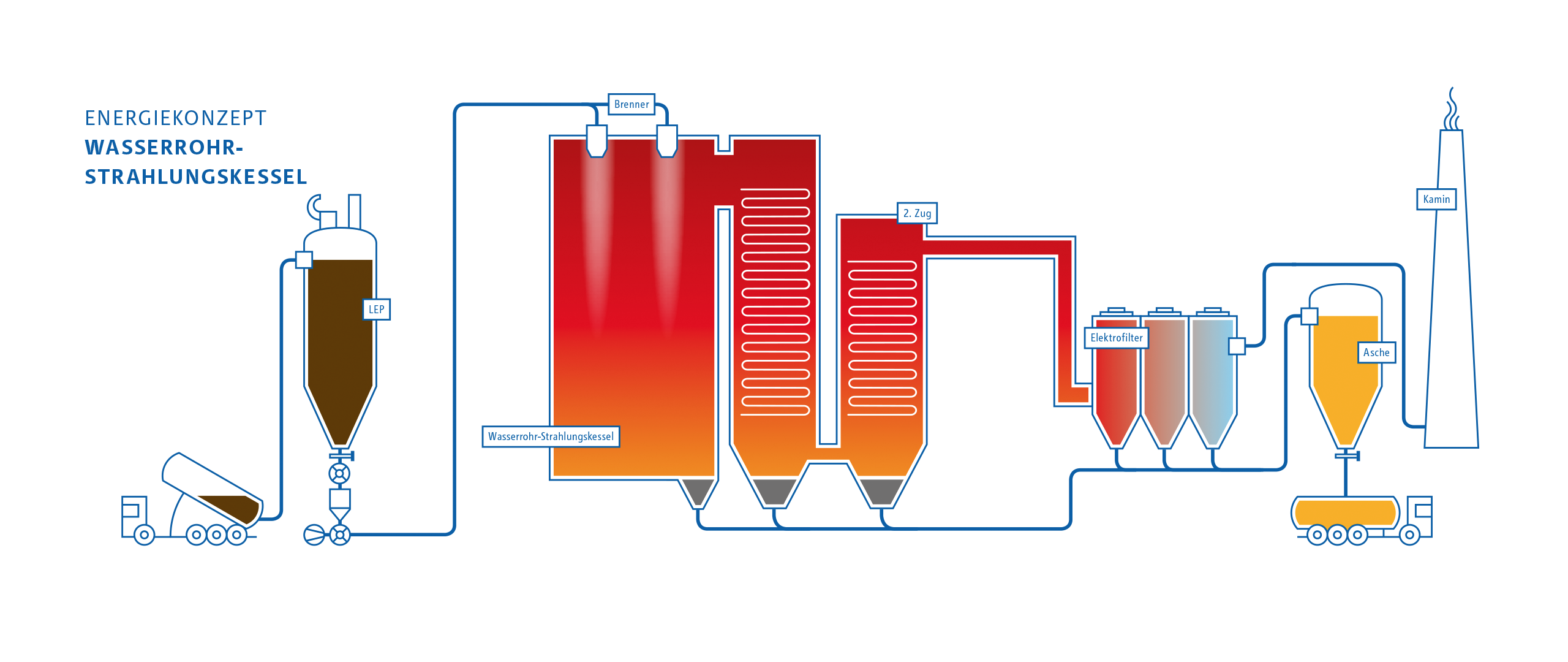

5 TO 20 MWTH

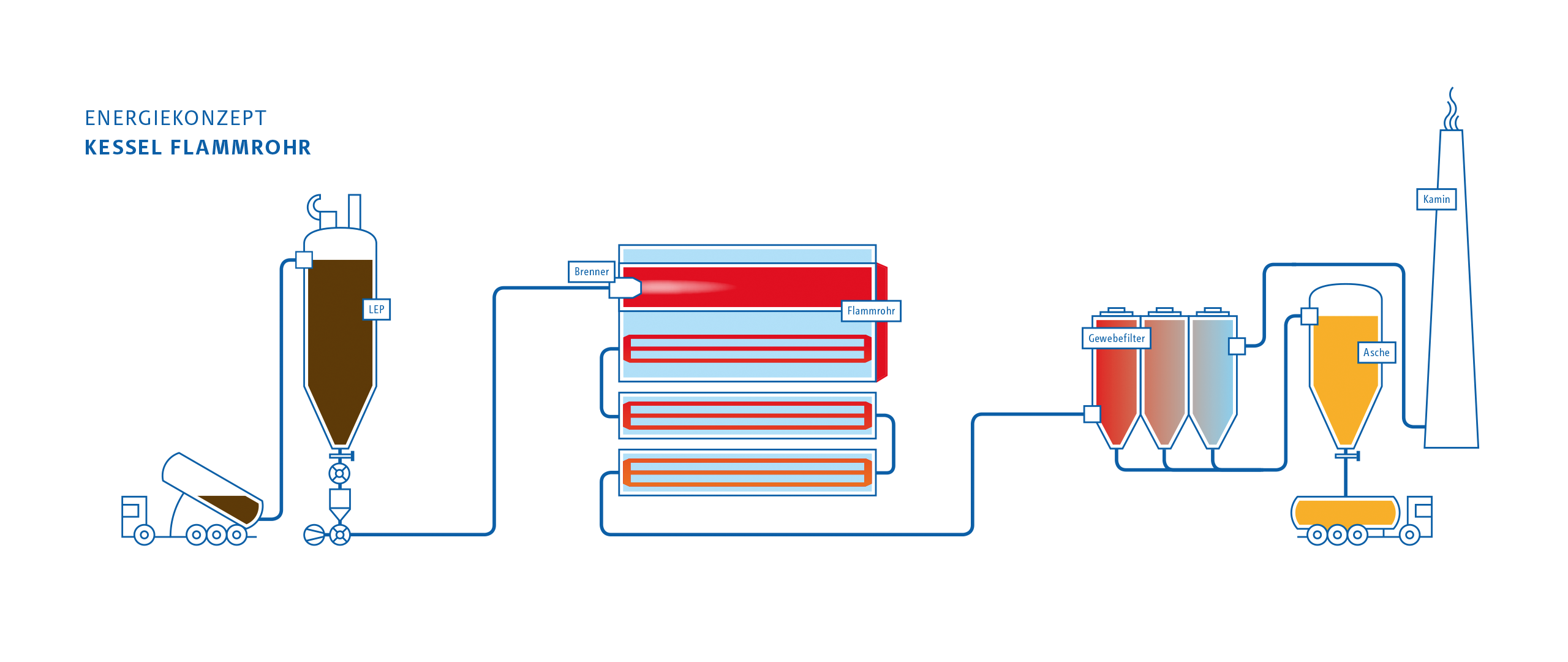

LEP is suitable for shell boilers with a capacity of 5 to 20 MWth. LEP can be used to fire low-pressure and high-pressure boilers. The boilers save space and have a high control speed. Both process steam and electricity can be generated in an energy-efficient way thanks to co-generation.

20 TO 200 MWTH

The use of LEP in flame-tube boilers with a capacity of up to 200 MWth is technically feasible and makes economic sense.

200 TO 300 MWTH

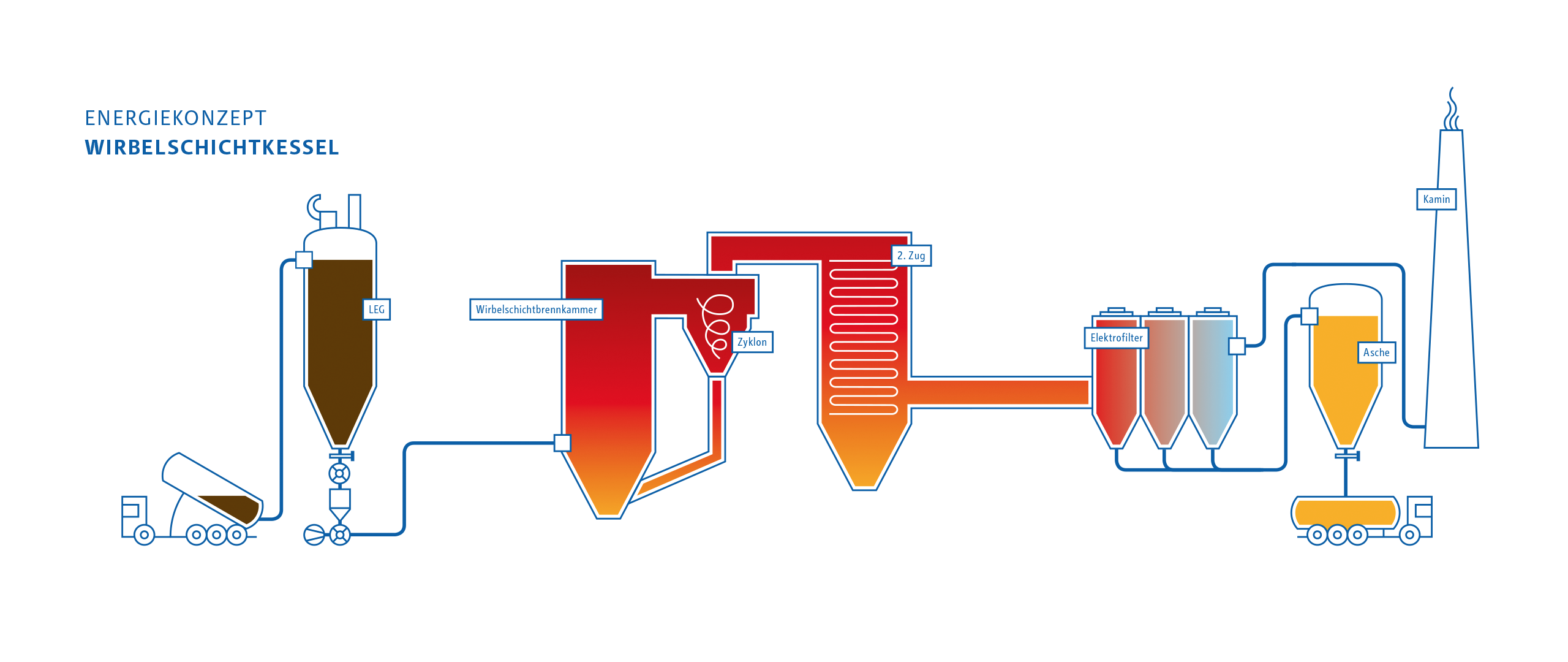

LEG is used in large, high-capacity plants with fluidized-bed combustion up to 300 MWth. Waste materials can also be used in the circulating fluidized-bed to produce thermal energy. This avoids disposal costs (for example, in the paper industry), makes the company independent of the disposal market and saves valuable primary energy.