LOW-COST ENERGY FOR THE ASPHALT INDUSTRY

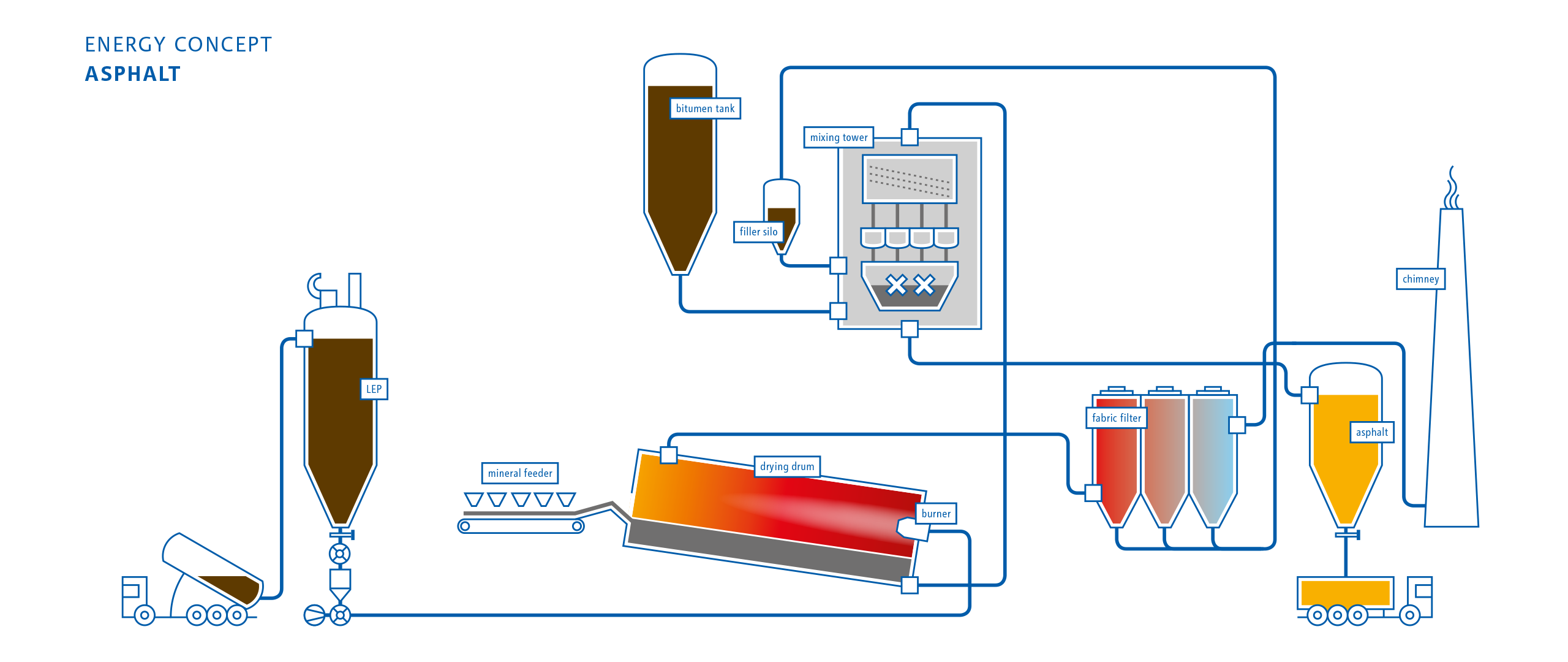

LEP Lignite Energy Pulverized is used in the vast majority of modern asphalt-mixing plants to provide energy for drying and heating processes. LEP is the market-leading energy source for the asphalt industry. The low-sulphur industrial fuel offers this energy-intensive sector benefits others cannot match.

HIGH CALORIFIC VALUE

LEP by Rheinbraun Brennstoff (RBB) contains a very high proportion of volatile matter at the same time as boasting a large surface. This ensures perfect burning characteristics for energy-efficient industrial processes.

OUTSTANDING PROFITABILITY

As an energy source available on our doorstep, LEP is a much more affordable source of energy than oil and gas, and available at far more stable prices. Long-term supply agreements mean energy costs can be calculated reliably in advance, making plants more profitable.

SIMPLE AND SAFE TO USE

LEP is easy and safe to use in closed systems. In fact, it is just as simple to use as an oil-powered system.

MEETS STATUTORY EMISSIONS GUIDELINES

LEP is a low-sulphur energy source, and the emissions it produces are comfortably within legal limits.

HIGH CONTROL SPEED

Thanks to their high control speed, LEP combustion plants are ideal for mixing asphalt in batches for non-continuous production.

CONVERSION QUICKLY

PAYS OFF

ENERGY-INTENSIVE INDUSTRIES

Asphalt-mixing plants running on oil or natural gas can often be converted using standardized components without the need for any great expenditure. Conversion can be expected to pay for itself within two to three years.

The pulverized fuel silo, feeding systems, conveyors and burner all take up relatively little space. The smallest of our pulverized fuel silos holds 60 tonnes of LEP. That is the same amount of energy as almost 40,000 litres of heating oil. A silo of that size is generally big enough to ensure a secure supply of fuel.

Rheinbraun Brennstoff ensures flexible just-in-time delivery with three production sites, two handling terminals in Ulm and Brandenburg an der Havel and our in-house logistics unit.

ANALYSIS REFERENCE VALUES LEP

| PROXIMATE ANALYSIS (A.R.) | |

|---|---|

| Water content | 11,0 % |

| Ash content | 4,0 % |

| Volatile matter | 45,0 % |

| Fixed carbon | 40,0 % |

| Net calorific value (NCV) | 22,2 MJ/kg |